Metal Working Automation

With decades of experience applying numerous methods for sheet metal assembly including clinching, hemming, brazing, soldering, thermo-stud installation, spot, resistance & laser welding, and standard fastener assembly methods, Ehrhardt Automation has the capability to provide creative, innovative manufacturing solutions that offer the lowest total cost of ownership (TCO) over the life of the equipment. From individual work cells to complete process lines, new builds or comprehensive retools, design, build and start-up of your application will be uniquely tailored to your specific needs and challenges to optimize Overall Equipment Effectiveness (OEE).

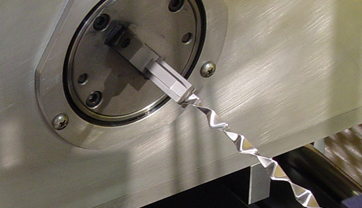

Metal Forming

When you are making the move to integrated automated manufacturing and robotic solutions for your business, you want confidence that the company you partner with understands your business, your needs and the unique challenges of your operation.

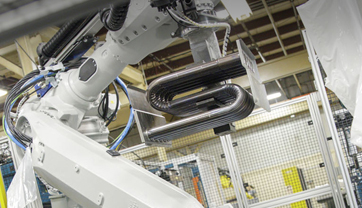

Brazing Automation Systems

When you work in the automotive, appliances, industrial, aerospace, HVAC, consumer or medical supply industries, your metal forming brazing needs will be specific to your operation, your risk tolerances, your industry standards and your manufacturing specifications.

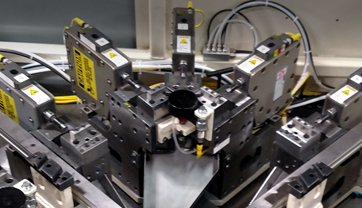

Crimping, Clinching & Swaging

Ehrhardt Automated Systems has extensive knowledge of these fundamental principles of metal forming and whether your operation requires joining round tubes to flat plates, sheet metal to molded parts or any other application that requires malleable...